1.Intelligent Automation Redefines the Future of Natural Gas Transmission Networks

1.1 From Manual Operations to Smart Systems: A Technological Leap Forward

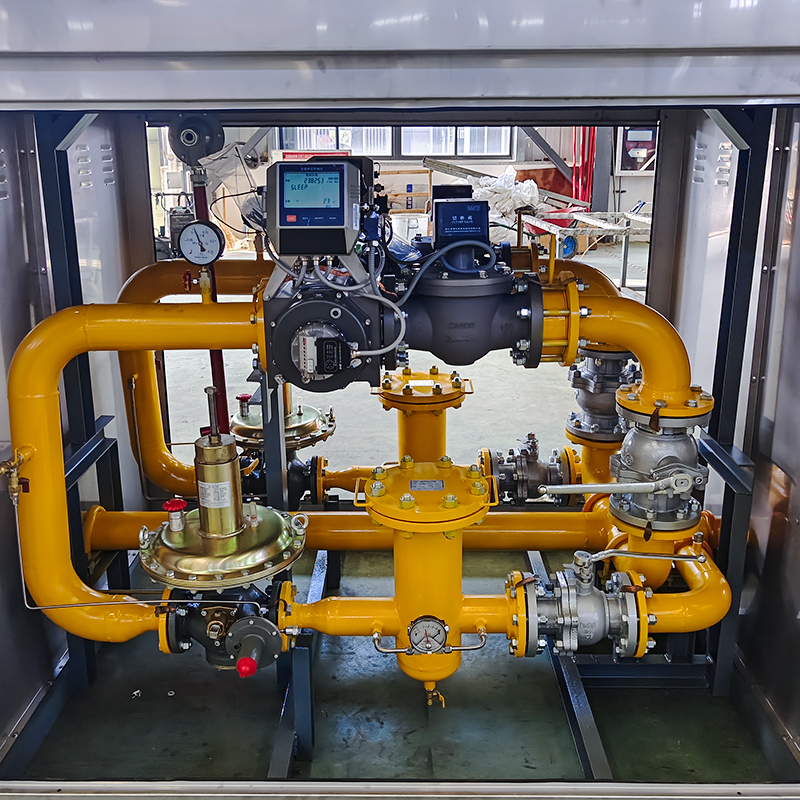

Traditional manual control in gas transmission systems is gradually being replaced by intelligent automation. Automatic control systems now offer real-time regulation of pressure, flow, and temperature across pipelines, enhancing both the operational safety and responsiveness of the network. This evolution reflects a broader trend toward smart energy infrastructure designed for precision and scalability.

1.2 Real-Time Data Acquisition Enhances Process Visibility

Integrated sensor networks collect and analyze operational data continuously, enabling real-time system feedback and decision-making. These intelligent systems provide comprehensive visibility into every transmission node, allowing operators to monitor and adjust parameters remotely from centralized control rooms. This digital integration lays the foundation for predictive maintenance and continuous optimization.

1.3 Autonomous Optimization Across Transmission Nodes

Automated controllers not only monitor but also dynamically adjust the function of equipment such as compressors and regulators. This ensures each segment of the transmission pipeline remains within its optimal performance envelope. The result is smoother transmission flow, fewer disruptions, and enhanced long-term infrastructure resilience.

2.Emergency Responsiveness and System Resilience Enhanced Through Automation

2.1 Instant Reaction to Pressure and Flow Deviations

Pipeline anomalies such as sudden pressure drops or surges can trigger immediate responses from the automated system. Intelligent valves can isolate affected sections within seconds, preventing cascade failures and minimizing the risk of gas leakage or explosion. This level of responsiveness far exceeds traditional manual intervention capabilities.

2.2 Integrated Safety Protocols Activate Without Delay

Advanced automatic control systems are equipped with pre-programmed emergency protocols that initiate corrective actions instantly. In the event of abnormal temperature rises or hazardous leaks, systems can activate backup routes, initiate cooling processes, or alert response teams automatically—thus significantly improving safety compliance and incident containment.

2.3 Disaster Prevention Through Predictive Intelligence

Beyond reacting to emergencies, these systems analyze trends to predict potential failures. Using historical and real-time data, predictive algorithms identify early signs of wear, leakage, or systemic imbalances. Preventive measures are then initiated proactively, reducing downtime, extending equipment lifespan, and ensuring uninterrupted gas delivery to end users.

3.Intelligent Control Systems Streamline Management and Elevate Energy Efficiency

3.1 Cross-System Coordination Enhances Operational Consistency

Natural gas transmission spans multiple functional nodes—including compression, regulation, and distribution. Automated control platforms ensure that these nodes operate in harmony by coordinating pressure and flow based on real-time demand. This unified management approach reduces internal bottlenecks and maintains consistent delivery pressure across vast networks.

3.2 Reduced Human Error and Maintenance Costs

By minimizing manual operation, intelligent systems reduce the likelihood of human-induced faults such as incorrect valve actuation or misjudged parameter settings. Automation also decreases wear and tear caused by improper handling, leading to lower maintenance demands and extended intervals between inspections.

3.3 Energy Efficiency Gains Support Sustainability Goals

Automated systems continuously fine-tune operations for optimal energy usage. By preventing over-compression, eliminating idle times, and avoiding redundant equipment runs, energy losses are minimized. These improvements align with global sustainability targets and deliver measurable reductions in operational carbon footprints.

English

English русский

русский Español

Español عربى

عربى

Contact Us