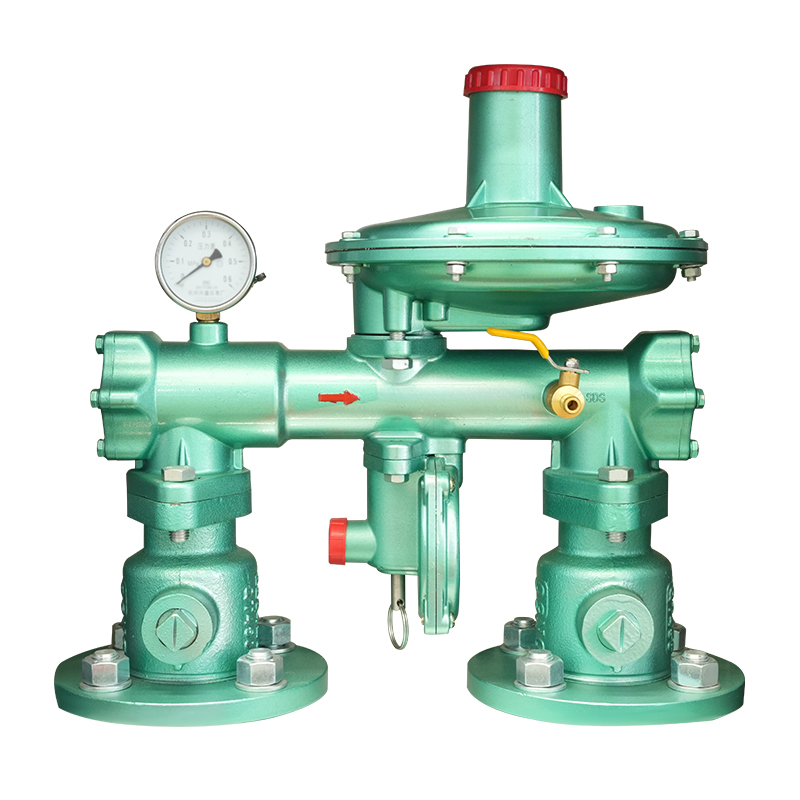

Natural gas valve pressure regulator gas regulating valve

LPG Pressure Regulator Industrial gas pressure regulator is a key device to ensure the safe use of gas. This regulating valve is mainly used to contro...

See DetailsIn the intricate tapestry of gas transmission and distribution systems, the gas pressure regulating box stands as a pivotal guardian, ensuring a consistent and secure supply. The initial step to guaranteeing its optimal performance and longevity is a meticulous selection process. When choosing a regulating box, several core performance parameters must be comprehensively evaluated. The first is the maximum design flow rate, which dictates whether the unit can adequately meet the maximum gas demand of downstream users, thus requiring a generous safety margin. Equally crucial are the inlet and outlet pressures, which define the box's operational range and its ability to regulate pressure, necessitating a precise match to both the upstream supply and the working pressure of downstream equipment. Pressure regulation accuracy is another critical metric, reflecting the unit's capability to maintain a stable outlet pressure across varying flow rates; a high-precision box better protects delicate downstream gas-consuming devices. Furthermore, environmental factors such as ambient temperature, humidity, and the presence of corrosive substances must be considered to select a unit with the appropriate protective rating and anti-corrosion treatment. Through a detailed analysis of these parameters and careful selection, one can ensure the chosen regulating box not only meets performance demands but also withstands complex operating conditions, thereby guaranteeing the safety and reliability of the entire system.

The dependable operation of a gas pressure regulating box hinges on diligent routine maintenance. Regular inspections are the cornerstone of identifying potential issues and averting accidents. Routine maintenance should include: checking the exterior of the box for any damage or corrosion; ensuring all bolts and connections are tight and leak-free; verifying that pressure gauges, flow meters, and other instruments display normal readings; and confirming that the safety shut-off valve and relief valve are in a ready state. During winter, low temperatures pose a unique set of challenges. Small amounts of water and heavy hydrocarbons in the natural gas can freeze or liquefy, clogging pipes, valves, and filters. To tackle this, several anti-freeze measures can be employed. For instance, installing a heating device inside or upstream of the box to keep the gas temperature above its dew point; applying anti-freeze insulation material to the inner and outer walls of the box; and fundamentally, installing a dehydration unit at the gas source to reduce the water content in the gas. These maintenance and anti-freeze strategies not only ensure the equipment operates normally during severe cold weather but also extend its overall service life.

A typical gas pressure regulating box houses several key components that work in concert to achieve precise control over gas pressure. The relief valve is a critical safety device; should the outlet pressure of the regulating box unexpectedly rise, it automatically opens to vent the excess gas into a safe area, preventing pressure overload. The filter, located at the front of the gas stream, is designed to remove impurities and particles from the gas, protecting the sensitive downstream regulators and metering equipment from damage. The safety shut-off valve is an automatic protective mechanism that, when the outlet pressure exceeds or falls below a preset value, automatically closes to cut off the gas supply, preventing the escalation of an incident. At the heart of the regulating box is the regulator, which senses the outlet pressure and automatically adjusts the valve's opening to maintain a stable outlet pressure. When the outlet pressure rises, the sensing diaphragm inside the regulator moves down, causing the valve to close and reducing the gas flow; conversely, it opens the valve to increase the flow. It is this sophisticated feedback and adjustment mechanism that enables the regulating box to achieve precise control over gas pressure, safeguarding downstream gas-consuming equipment.

During its long-term operation, a gas pressure regulating box may inevitably encounter various faults, making a systematic approach to diagnosis essential. Common faults include unstable outlet pressure, persistent abnormal noise, and obvious leaks. If the outlet pressure fluctuates continuously, one should first check if the upstream pressure is stable; if it is, the issue might be with the regulator's internal diaphragm, valve core, or spring. Abnormal noises, such as a sharp whistling sound, are often caused by the valve core vibrating or cavitating under high-speed gas flow, which may require cleaning or replacement of parts. Leaks represent the most dangerous fault and can be detected using soapy water or a gas leak detector, with a focus on flanges, connections, valves, and instrument fittings. Upon detecting a leak, immediate action is imperative: shut off the upstream valve and contact a professional for repairs. For any fault, the principle of "diagnose first, then repair" should be followed to avoid haphazard disassembly, which could lead to greater safety risks. By following a systematic troubleshooting guide, problems can be quickly pinpointed, and correct measures can be taken to ensure the safe, efficient, and reliable operation of the gas pressure regulating system.

Contact Us