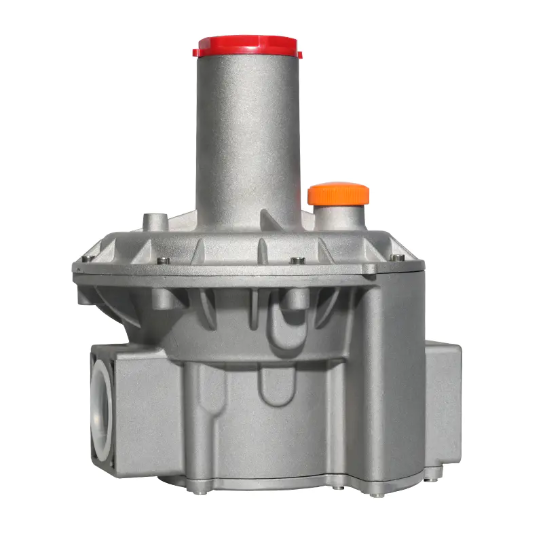

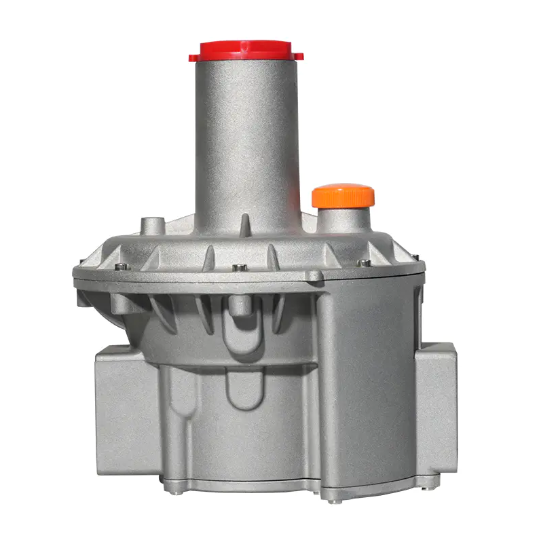

LPG Pressure reducing valve, regulator

Gas pressure reducing valve for natural gas/liquefied gas/petroleum gas high-pressure regulator is widely used in natural gas, liquefied gas, petroleu...

See Details1. Ensuring Pressure Precision: The Core Regulatory Role of Gas Pressure Regulators

1.1 Navigating Pressure Fluctuations Across Complex Terrains

Natural gas pipelines often span long distances, passing through varying elevations, environmental conditions, and operational demands. These natural variations lead to inconsistent pressure levels along the network. Pipeline Gas Pressure Regulators play a crucial role in smoothing out these discrepancies, adjusting input and output pressures to remain within safe operational thresholds.

1.2 Real-Time Sensing and Autonomous Balancing Mechanisms

Advanced regulators are equipped with sensors and automatic control logic that detect fluctuations in real time. Whether triggered by a sudden change in flow rate, ambient temperature, or pipeline configuration, the regulator instantly recalibrates to maintain consistent pressure. This dynamic balancing ensures that the system remains efficient and avoids energy waste due to pressure imbalances.

1.3 Enhancing Operational Safety through Predictive Control

Uncontrolled pressure changes can damage equipment or lead to hazardous events such as leaks or explosions. Regulators serve as the frontline defense, stabilizing pressure before it affects the rest of the system. Their ability to adjust swiftly and maintain equilibrium prevents cascading failures and reinforces the structural integrity of the gas transmission network.

2. Mastering Complex Environments: Adaptive Control for Dynamic Gas Systems

2.1 Handling Pressure Drop and Surge Scenarios with Precision

Pipelines are affected by bends, valves, and varying resistance zones, which can either drop or amplify gas pressure unpredictably. Pipeline Gas Pressure Regulators respond to these dynamic shifts by altering valve positions and flow rates instantly, ensuring that downstream equipment operates within expected parameters.

2.2 Intelligent Automation for Self-Correcting Regulation

Equipped with automated logic, modern regulators analyze multiple variables—flow speed, upstream/downstream pressure differentials, and valve positions—to self-correct imbalances. When upstream pressure rises, the regulator restricts flow; when it drops, it opens pathways to maintain steady delivery. This intelligent adjustment supports uninterrupted, balanced flow even during peak demand or system disturbance.

2.3 Emergency Readiness and Multi-Level Redundancy Protection

Pipeline Gas Pressure Regulators incorporate multiple layers of safety protocols, including emergency shutoff features and redundant adjustment circuits. In case of abnormal surges, the system can isolate affected areas, restore stability, and prevent broader system disruptions. This design ensures resilience, especially in high-risk or high-pressure zones where rapid intervention is critical.

3. Driving Efficiency and Innovation: The Future of Gas Flow Regulation

3.1 Supporting Continuous and Responsive Gas Supply

In a demand-driven system, energy utilities must adapt to hourly and seasonal fluctuations in consumption. Regulators act as precision instruments, fine-tuning pressure output to match real-time needs—whether ramping up flow during industrial peak hours or scaling down for residential quiet periods—without compromising delivery consistency.

3.2 Reducing Downtime and Enhancing Overall System Reliability

By minimizing manual intervention and optimizing system balance, Pipeline Gas Pressure Regulators reduce operational strain on both infrastructure and human resources. This translates into lower maintenance costs, fewer emergency repairs, and longer equipment life cycles, enhancing the return on infrastructure investments.

3.3 Becoming a Smart Node in Next-Generation Energy Grids

As the industry shifts toward digital integration and intelligent systems, gas pressure regulators are evolving from passive devices to smart, connected nodes. Future models will integrate with SCADA systems, utilize AI-based predictive analytics, and share data across the grid to forecast pressure trends and prevent issues before they arise—marking a transition from regulation to system-wide orchestration.

Contact Us