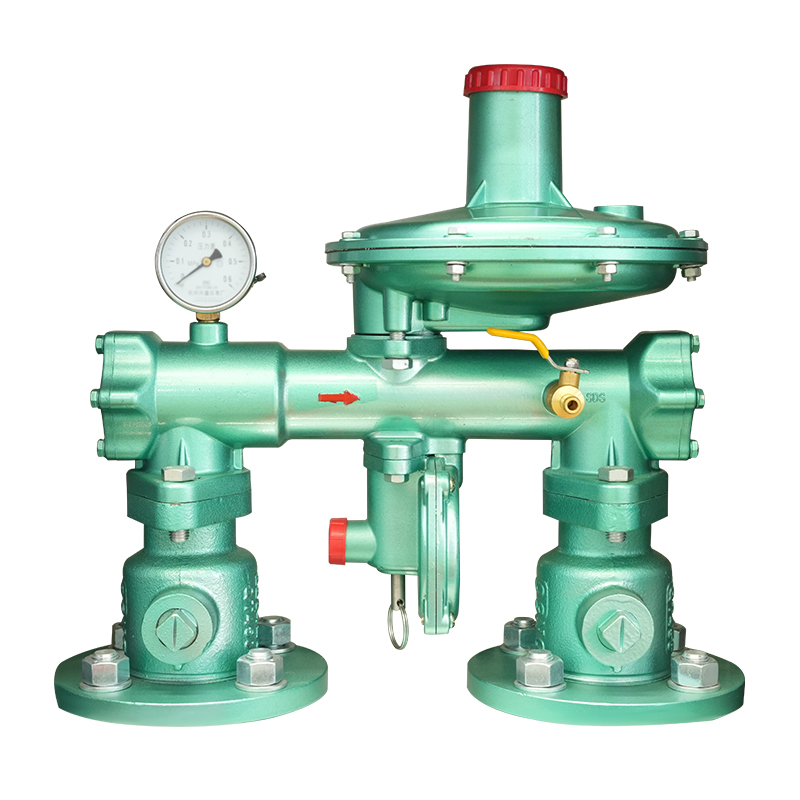

LPG Pressure reducing valve, regulator

Gas pressure reducing valve for natural gas/liquefied gas/petroleum gas high-pressure regulator is widely used in natural gas, liquefied gas, petroleu...

See DetailsA Gas Pressure Regulating Box is a critical piece of safety equipment designed to receive high-pressure gas from a utility line or storage tank and reduce it to a safe, usable level for downstream appliances and equipment. These enclosures, often called gas trains or regulator sets, are more than just a box; they are engineered systems that ensure pressure stability and incorporate multiple safety mechanisms. Selecting the right one is paramount for operational efficiency, regulatory compliance, and most importantly, the safety of personnel and property. A failure in pressure regulation can lead to equipment damage, hazardous gas leaks, or even catastrophic explosions, making a thorough understanding of these systems essential for anyone involved in specifying or installing gas equipment.

At its core, a Gas Pressure Regulating Box houses a complete pressure regulation assembly. This assembly typically includes a primary regulator to control the pressure, a safety relief valve or vent to release excess pressure in a failure scenario, and often an over-pressure shut-off valve (slam-shut valve) that completely stops gas flow if pressure exceeds a safe limit. These components work in concert to create a fail-safe system. The enclosure itself protects these sensitive instruments from environmental damage, unauthorized tampering, and accidental impact, ensuring reliable and safe operation over many years.

Understanding the function of each component is key to understanding the system's safety. The regulator modulates the pressure. The relief valve acts as a pressure "safety net," venting gas to prevent the system from over-pressurizing. The slam-shut valve is the final line of defense, completely cutting off the gas supply if the regulator fails and pressure reaches a critical setpoint. This layered safety approach is fundamental to modern gas system design.

| Component | Primary Function | Why It's Critical |

| Regulator | Reduces inlet pressure to a stable outlet pressure | Ensures appliances receive gas at their correct operating pressure |

| Relief Valve | Vents excess pressure to the atmosphere | Prevents system rupture or explosion due to over-pressurization |

| Slam-Shut Valve | Automatically shuts off gas flow at a preset pressure | Provides a fail-safe to stop gas supply if the regulator fails |

Compliance with recognized standards is non-negotiable. In North America, standards from the American Society of Mechanical Engineers (ASME) and the Canadian Standards Association (CSA) are the benchmark for safety and performance. In Europe, the CE mark indicates conformity with health, safety, and environmental protection standards. These certifications mean the product has been independently tested and meets stringent design, manufacturing, and testing requirements. When sourcing a Gas Pressure Regulating Box, always verify it carries the appropriate certifications for your region to ensure it meets all legal and safety requirements.

The demands placed on a pressure regulating system vary dramatically depending on the application. A small commercial kitchen has vastly different needs than a large industrial boiler or a gas-fired power plant. The primary considerations are the inlet pressure from the gas main, the required outlet pressure for the equipment, and the total flow capacity needed. Selecting a system that is correctly sized for its intended application is crucial for performance and longevity. Undersizing a unit will lead to pressure drops and poor appliance performance, while oversizing can lead to instability and unnecessary cost.

A high pressure gas regulator box is required in industrial settings, utility receiving stations, or any application where the gas supply pressure is significantly higher than standard commercial pressure. These systems are engineered to handle inlet pressures that can range from tens to hundreds of PSI (pounds per square inch). They feature robust construction, heavy-duty regulators, and enhanced safety features to manage the greater forces involved. Using a standard-duty box in a high-pressure application is extremely dangerous and a violation of safety codes.

For high-pressure applications, the choice between single-stage and two-stage regulation is critical. A single-stage system reduces pressure in one step. While simpler, it can be less stable, especially with fluctuating inlet pressures or variable downstream demand. A two-stage system reduces the pressure in two steps (e.g., from high pressure to an intermediate pressure, then to the final outlet pressure). This provides superior outlet pressure stability, making it the preferred choice for sensitive industrial equipment and applications with consistent, high flow demands.

| Regulation Type | Best For | Advantages | Disadvantages |

| Single-Stage | Lower inlet pressures, stable demand | Lower cost, simpler design | Less stable with fluctuating pressure/demand |

| Two-Stage | High inlet pressures, sensitive equipment | Excellent pressure stability, safer | Higher cost, more complex |

When specifying a Gas Pressure Regulating Box, three numbers are paramount: maximum inlet pressure, desired outlet pressure, and required flow capacity (measured in SCFH - Standard Cubic Feet per Hour, or m³/h). The inlet pressure must be equal to or greater than the supply pressure. The outlet pressure must match the requirements of all connected appliances. The flow capacity must be high enough to meet the combined demand of all appliances operating simultaneously without causing a significant pressure drop.

Where the Gas Pressure Regulating Box will be installed is a major factor in its design and material selection. An indoor installation in a clean, dry boiler room has very different requirements than an outdoor installation exposed to rain, snow, temperature extremes, and potential physical damage. The enclosure must be robust enough to protect the sensitive internal components from the specific environmental challenges it will face throughout its service life.

For a natural gas regulator enclosure for outdoor applications, durability and weatherproofing are the top priorities. These enclosures are typically constructed from heavy-gauge steel or aluminum and feature a durable powder-coated finish to resist corrosion and UV degradation. A critical feature is proper ventilation. The enclosure must be designed to allow any gas leaks from internal components to vent safely upwards and away from the structure, preventing the accumulation of gas inside the box. This is a mandatory safety feature specified in all installation codes.

The choice of material and coating directly impacts the longevity of an outdoor enclosure. While painted steel is common, it can be prone to rust if the coating is damaged. Aluminum offers excellent natural corrosion resistance but may not be as robust against impact. For highly corrosive environments, such as coastal areas or industrial facilities, stainless steel enclosures provide the ultimate durability. The quality of the powder coating is also crucial; a high-quality, thermoset powder coat will provide a much tougher and more resilient finish than standard paint.

| Material | Pros | Cons | Best Environment |

| Painted Steel | High strength, cost-effective | Prone to rust if coating is damaged | General outdoor use, non-corrosive |

| Aluminum | Excellent corrosion resistance, lightweight | Softer, less impact resistant | Coastal/moist climates |

| Stainless Steel | Superior corrosion and impact resistance | Higher cost | Harsh industrial, chemical, marine |

Proper ventilation is achieved through louvered panels or vents designed according to specific code requirements. The Ingress Protection (IP) rating is another important consideration. An IP rating (e.g., IP54) defines the level of protection against solid objects (like dust) and water (like rain). A higher second digit indicates better water protection. For outdoor installations, an IP rating of at least IP54 is typically recommended to ensure the enclosure can withstand rain and splashing water without compromising the internal components.

Different types of gas have unique properties that require specific design considerations in a Gas Pressure Regulating Box. Natural gas, which is primarily methane, behaves differently than propane (LPG), which is heavier than air and stored as a liquid under pressure. Furthermore, the quality of the gas itself is a factor. Pipeline gas can contain contaminants like pipe scale, oil, and moisture, which can damage sensitive regulator components. Therefore, filtration is often a necessary addition to ensure long-term reliability.

A propane gas regulator box with filter is essential for any application using LPG stored in a bulk tank. As propane is drawn from the tank, it can carry impurities from the bottom of the tank, such as rust, scale, and oil. These contaminants can easily clog the small orifices and mechanisms inside a pressure regulator, causing it to fail. A sediment filter, installed upstream of the regulator, traps these particles, protecting the regulator and ensuring a clean, reliable gas flow to downstream equipment. This is a critical maintenance and reliability feature for any propane system.

Filters are rated by the size of particles they can trap, measured in microns. A typical sediment filter for a gas application might have a rating of 10 to 50 microns. The choice of media is also important; common materials include sintered metal and stainless steel mesh, which are compatible with natural gas and propane. The filter must also be designed to handle the system's pressure and flow rate without causing a significant pressure drop itself. Regular inspection and cleaning or replacement of the filter element are crucial maintenance tasks.

| Filter Feature | Description | Importance |

| Micron Rating | Size of particles the filter traps (e.g., 10-micron) | Determines the level of protection for the regulator |

| Filter Media | Material used to trap particles (e.g., sintered bronze) | Must be compatible with the gas type and pressure |

| Differential Pressure | The pressure drop across the filter element | Must be low enough to not affect system performance |

The materials used for seals and diaphragms inside the regulator must be compatible with the specific gas. Certain elastomers and polymers can degrade or swell when exposed to the heavier hydrocarbons found in LPG. For this reason, regulators intended for propane service often use materials like Buna-N or specific fluorocarbon compounds, while those for natural gas may use different materials. Always ensure that any Gas Pressure Regulating Box is specifically rated and certified for the type of gas it will be handling.

In commercial construction, efficiency and reliability are key. Projects like restaurants, hospitals, and schools require a dependable gas supply for multiple appliances. Specifying individual components and assembling them on-site can be time-consuming, prone to error, and may not result in the most optimized system. An integrated solution that combines measurement and regulation into a single, factory-assembled unit offers significant advantages in terms of installation speed, performance, and compliance.

A commercial gas meter and regulator set is a pre-assembled and pre-tested unit that houses the gas utility's meter alongside the necessary pressure regulating equipment. By integrating these components into a single, cohesive system, it streamlines the installation process. The utility company can easily install their meter, and the building contractor receives a fully functional and code-compliant pressure regulating system. This eliminates the need for multiple vendors and complex field fabrication, reducing labor costs and the potential for installation errors.

These integrated sets are designed to meet all relevant local and national codes right out of the box. The manufacturer has already ensured that the pipe sizing, component selection, and safety features are correctly configured for the specified load. This not only speeds up the installation but also simplifies the inspection process, as inspectors are dealing with a certified, complete system rather than a collection of individual parts assembled on-site. This significantly reduces the risk of non-compliance and costly rework.

| Benefit | Integrated Set | Traditional Field Assembly |

| Installation Time | Fast, simple connection | Slow, requires skilled labor |

| Compliance Risk | Low (pre-certified) | High (dependent on field work) |

| Performance | Guaranteed and tested | Variable, depends on assembly quality |

The primary advantage of a factory-built set is quality control. The entire assembly is constructed in a controlled environment by skilled technicians. Before it leaves the factory, it undergoes a series of pressure and leak tests to ensure every connection is sound and the system operates as designed. This level of verification is nearly impossible to achieve with the same consistency on a busy construction site, making the integrated set a far more reliable and safer option for any commercial gas application.

Sizing a gas pressure regulator correctly is crucial for system performance. You need three key pieces of information: the required outlet pressure (specified by the appliance manufacturer), the maximum inlet pressure (from the gas utility), and the total gas flow rate (the sum of all appliance loads, converted to SCFH or m³/h). With this data, you can consult a regulator manufacturer's capacity chart, which plots flow rate against pressure drop, to select a regulator model that can handle your required flow at your specific inlet/outlet pressure differential without exceeding its capacity. It's always best to choose a regulator with some capacity margin to handle future demand.

Installing a Gas Pressure Regulating Box is not a DIY job. It involves working with high-pressure, flammable gas and must comply with strict local and national plumbing and gas codes. These installations must be performed by a licensed and qualified professional plumber or gas fitter. An improper installation can lead to gas leaks, fire, explosion, and carbon monoxide poisoning, posing a lethal risk. Furthermore, an incorrect installation will void the product's warranty and may result in legal and insurance issues.

Both are safety devices, but they function differently. A relief valve is designed to open and vent gas to the atmosphere if the pressure downstream of the regulator exceeds its setpoint, preventing over-pressurization of the downstream system. A vent limiter, on the other hand, is a device that limits the rate at which gas can be vented from the regulator's relief vent. It is used to prevent a large, uncontrolled release of gas in the event of a regulator failure, making it a critical safety feature, especially for indoor installations. Many modern regulators incorporate a vent limiter as part of their design.

An explosion proof gas regulator box is required in environments where flammable gases or vapors are present in the atmosphere under normal operating conditions (hazardous locations). These locations are classified by standards like NEC in the US or ATEX/IECEx internationally. An explosion proof enclosure is designed to contain an internal ignition (like an electrical spark) and prevent it from igniting the surrounding explosive atmosphere. It does not mean the box is indestructible, but rather that it is engineered to isolate any internal explosion from the outside environment. Using a standard enclosure in such a location would be extremely dangerous and a severe violation of safety regulations.

The service interval for a gas pressure regulator depends on the application, gas cleanliness, and manufacturer's recommendations. For critical industrial applications, annual inspection and testing are common. For commercial applications, a check every 2-5 years is often sufficient. During a service, a technician will check the outlet pressure for stability, verify the operation of the safety shut-off and relief devices, inspect the filter, and check for any signs of leakage or corrosion. It's crucial to follow the manufacturer's guidelines and local codes, as a neglected regulator is a serious safety hazard.

Contact Us