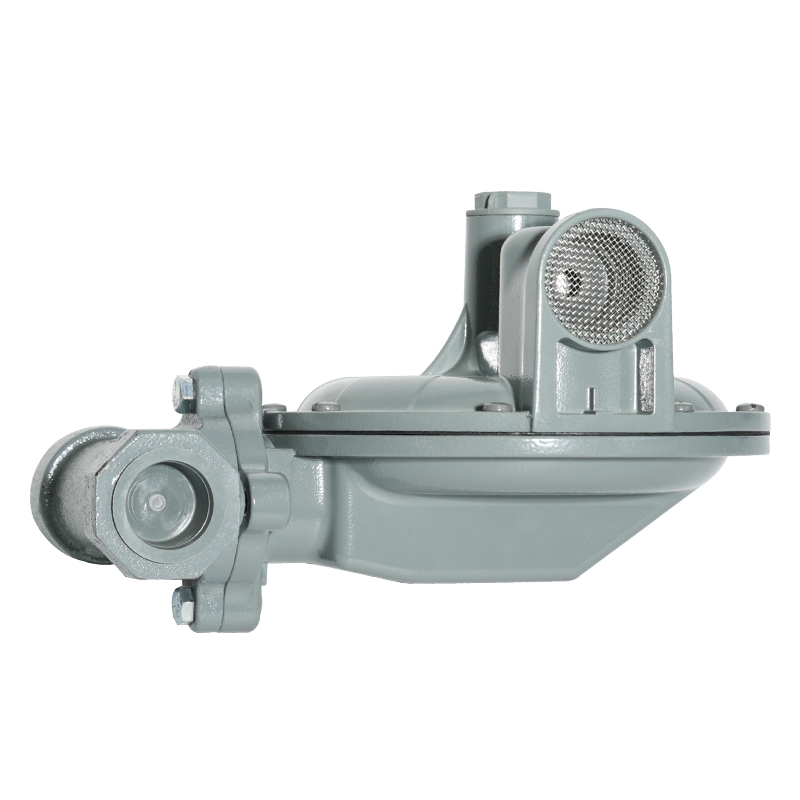

LPG Pressure reducing valve, regulator

Gas pressure reducing valve for natural gas/liquefied gas/petroleum gas high-pressure regulator is widely used in natural gas, liquefied gas, petroleu...

See DetailsA pressure regulator is fundamentally a sophisticated type of control valve designed to reduce a high, potentially fluctuating inlet pressure from a gas source or line to a lower, constant outlet pressure required by a downstream system. This action is essential for the effective management of energy within fluid systems, ensuring that sensitive equipment operates within its designed parameters and preventing catastrophic failure due to over-pressurization. The core mechanism operates on a principle of force balance, where a loading element, typically an adjustable spring, exerts a downward force on a sensing element, which in turn acts on a restricting element, often a poppet valve, to open the flow path. As gas flows through the restriction and the downstream pressure builds, this pressure exerts an opposing force on the sensing element, causing the valve to modulate toward a more closed position until the forces are in equilibrium. This continuous, self-correcting feedback loop is what allows a pressure regulator to maintain a steady delivery pressure despite variations in supply pressure or changes in downstream demand.

For applications that demand exceptional stability and precise control over extended periods, particularly those involving high-pressure gas cylinders, the two-stage gas pressure regulator offers significant advantages. Unlike single-stage models that perform the entire pressure reduction in one step, a two-stage regulator divides the process into two separate, consecutive steps. The first stage reduces the cylinder's initial high pressure to an intermediate, pre-set pressure. This intermediate pressure is then fed into the second stage, which performs the final reduction to the required working pressure. This dual-reduction process effectively isolates the final delivery pressure from the wide decay of the inlet pressure that occurs as the gas cylinder is depleted. Consequently, two-stage regulators exhibit superior stability, requiring less frequent adjustment and offering a more consistent flow rate, which is a critical necessity in laboratory work, analytical instrumentation, or long-term high-pressure industrial feeding systems. Selection for such demanding scenarios must account for the required output pressure range and the capacity to handle the maximum expected inlet pressure from the source.

The phenomenon known as "droop" is an inherent characteristic of pressure regulation, describing the slight, undesirable fall in outlet pressure that occurs as the flow rate through the regulator increases. In high-pressure and high-flow environments, minimizing this effect is paramount to maintaining process integrity. High-pressure regulators are specifically engineered to mitigate droop through a combination of design features. One key factor is the effective area of the sensing element; larger diaphragms or pistons can provide a greater force balance area, resulting in more minute and accurate valve adjustments. Furthermore, the stiffness and design of the loading spring are carefully chosen to ensure a minimal change in spring force across the full range of the valve's movement. Advanced high-pressure designs may also incorporate balanced valve seats, which reduce the impact of changing inlet pressure on the valve's opening force, thereby allowing the regulator to react more precisely and maintain the set pressure closer to the ideal value, even under elevated flow conditions.

The choice between a diaphragm and a piston as the sensing element dictates many of the regulator's performance characteristics, particularly its responsiveness and the maximum pressure it can safely control. Diaphragms, typically constructed from flexible materials like polymers or metal, offer a large surface area for the downstream pressure to act upon, providing exceptional sensitivity and allowing for very precise control over low to moderate pressure ranges. They are prized for applications requiring high accuracy and minimal pressure deviation. Conversely, pistons, which are rigid and generally made of metal, are used in very high-pressure applications where the forces involved would compromise the structural integrity of a diaphragm. While pistons may exhibit slightly less sensitivity due to friction from seals and a smaller effective area, their robust construction allows them to safely handle extreme inlet pressures, often thousands of pounds per square inch, making them the standard for controlling compressed industrial gases from high-pressure lines or cylinders.

The accuracy with which a high-flow gas pressure regulator can maintain its set output pressure is not solely dependent on its internal mechanism but is also heavily influenced by several external and internal factors. The size of the valve's restricting element, defined in part by its flow coefficient , is crucial; an improperly sized orifice can lead to velocity effects that introduce turbulence and reduce control stability. Material selection for the valve seat and seals is also a significant factor, as these elements must resist the erosive effects of high-velocity gas and maintain sealing integrity across the operating temperature range. Moreover, the temperature of the gas itself affects its density, which can subtly alter the energy dynamics as the gas expands across the regulator's seat. Achieving true high-flow accuracy often requires careful system design to minimize upstream particulates and to ensure that the regulator is sized to operate in its most stable control range, avoiding both conditions of extreme throttling and fully open flow.

When a gas pressure regulator fails to maintain a steady outlet pressure, exhibiting undesirable fluctuations, it often points to a component malfunction or an operational mismatch with the system. Common causes include contamination, such as particulate matter or debris lodging on the valve seat, which prevents the valve from fully closing and leads to a gradual pressure creep or excessive lockup. Another frequent issue is internal wear or fatigue of the sensing element, such as a cracked diaphragm or worn piston seals, which compromises the force balance mechanism. A subtle but frequent problem is regulator oversizing, where the valve is constantly operating near the fully closed position, leading to "chattering" or instability. Troubleshooting begins with isolating the regulator and inspecting for signs of visible damage or contamination. Correction often involves replacing worn internal parts, installing appropriate upstream filtration to prevent future contamination, or, in the case of oversizing, replacing the unit with a regulator that has a lower flow capacity, ensuring it operates in the middle of its stable control curve. Proper initial spring loading and system venting are also vital practices for stable operation.

Contact Us