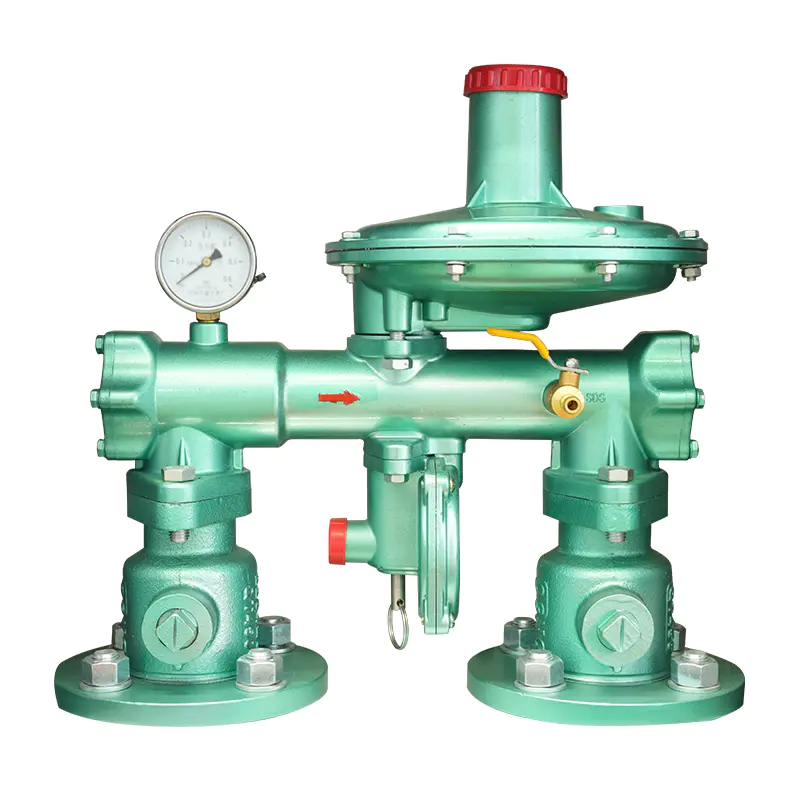

High pressure regulating valve, gas pressure regulating valve, pressure regulator

Safety valve gas control pump accessories pressure regulator is an indispensable key component in the gas system. As a protective device, the safety v...

See DetailsIn the complex infrastructure of modern energy distribution, the safe and efficient transport of natural gas is a priority that cannot be compromised. As gas travels from high-pressure transmission lines to the low-pressure systems required for residential and commercial use, it must pass through critical pressure reduction stations. These stations house sensitive mechanical equipment that must function flawlessly despite being exposed to harsh environmental conditions. This is where the Gas Pressure Regulating Box becomes an indispensable asset. These specialized enclosures are designed not merely to contain equipment, but to actively preserve the integrity of the pressure regulation system against weather, physical damage, and unauthorized access. By investing in a high-quality regulating box, utility companies and industrial facility managers can ensure a consistent gas supply, extend the lifespan of their regulators, and, most importantly, adhere to rigorous safety standards. This article explores the critical aspects of these enclosures, from environmental durability to safety compliance, illustrating why they are a fundamental component in modern gas distribution networks.

One of the primary functions of a protective enclosure is to shield sensitive internal components from the elements. A Gas Pressure Regulating Box is often installed in open fields, industrial zones, or residential areas where it is constantly exposed to rain, snow, UV radiation, and extreme temperature fluctuations. Without adequate protection, the pressure regulators and meters inside would suffer from corrosion, freezing, or mechanical degradation. An outdoor gas pressure regulator enclosure is specifically engineered to mitigate these risks. These units are typically constructed from heavy-gauge steel or aluminum, often finished with advanced powder coatings that resist chipping and rust. Furthermore, the design includes proper sealing and insulation to prevent the formation of ice inside the unit during winter, which is a common cause of regulator failure in colder climates. By maintaining a stable internal environment, the enclosure ensures that the gas pressure remains constant regardless of the weather outside.

As a dedicated manufacturer in this sector, we understand that durability is not just about material thickness but about intelligent design. A weatherproof gas regulator housing incorporates features like raised floors to prevent water ingress during flooding, double-skinned doors for improved insulation, and strategic ventilation points that allow air circulation while blocking rain and debris. These architectural details are crucial for maintaining the operational readiness of the gas infrastructure. Our commitment to quality manufacturing ensures that every box we produce acts as a fortress for the equipment within, capable of withstanding decades of environmental abuse without failing.

To understand the material advantages, the following table compares the properties of common materials used in the construction of these enclosures.

td>td>

| Material | Corrosion Resistance | Impact Resistance | Cost Efficiency |

| Stainless Steel (304/316) | High (Extremely durable) | Lower (High material cost) | |

| Galvanized Steel | Good (Zinc coating protects base metal) | High (Strong and cost-effective) | |

| Powder-Coated Aluminum | Excellent (Natural oxide layer) | Medium (Lighter, dent-prone) | |

| Fiberglass/Composite | Low (Can crack on impact) | High (Low installation cost) |

In industrial settings, the stakes are significantly higher due to the sheer volume of gas being transported and the operating pressures involved. An industrial natural gas regulator cabinet must be robust enough to handle the rigorous demands of factories, power plants, and large-scale commercial facilities. These cabinets are not just passive containers; they are active safety systems equipped with pressure relief vents, gas detection sensors, and explosion-proof electrical components. The primary safety concern in any gas regulation system is the potential for overpressure. If the regulator fails, gas pressure can spike downstream, leading to dangerous leaks or equipment damage. Therefore, industrial cabinets are designed to channel vented gas safely away from the enclosure, often utilizing piped vent stacks that discharge above the roofline, preventing gas accumulation at ground level.

Managing high-pressure flow requires specialized equipment, and the housing must be equally specialized. A high pressure gas regulator box is built with reinforced structural integrity to withstand the dynamic forces exerted by high-velocity gas flow. Safety codes, such as those set forth by ASME or local utility authorities, dictate strict requirements for these units, including flame arrestors and specific door latching mechanisms that prevent accidental opening but allow easy access for emergency personnel. As a manufacturer, we adhere to these global standards to ensure that every cabinet we ship contributes to a safer industrial environment.

The table below highlights the differences in safety features required for standard residential setups versus high-demand industrial applications.

| Safety Feature | Residential/Light Commercial | Industrial Cabinet |

| Venting System | Low-level vent slots | Piped Vent Stack (Above roof discharge) |

| Construction Material | Sheet Metal (20-22 gauge) | Heavy Gauge Steel (10-14 gauge) |

| Gas Monitoring | Visual inspection window | Integrated Sensor Ports (Electronic monitoring) |

| Access Control | Standard lock | Heavy-Duty Padlock or Tamper-Proof Latch |

The longevity and reliability of a Gas Pressure Regulating Box are heavily dependent on correct installation and ongoing maintenance. Siting is the first critical step; for example, a gas station pressure regulating cabinet must be placed in a location that is accessible for service vehicles but protected from vehicular impact. It requires a solid, level concrete base to prevent settlement, which could stress the inlet and outlet piping connections. Furthermore, the installation must account for future maintenance needs, ensuring that technicians have sufficient clearance to open doors fully and remove regulators if necessary. Proper clearances from building openings, property lines, and sources of ignition are not just recommendations—they are legal requirements that ensure the safety of the public and the facility.

Once installed, a routine maintenance schedule is vital. Technicians should regularly inspect the enclosure for signs of physical damage, corrosion on the door hinges, or blockages in the ventilation passages. For the gas station pressure regulating cabinet, specific attention must be paid to the sump and drain areas, as fuel spills or road grime can sometimes accumulate near the unit. As a manufacturer, we design our cabinets with maintenance in mind, using hardware that resists seizing and finishes that are easy to clean. We also provide detailed guidelines to our clients on how to perform these inspections effectively.

The following table outlines the common maintenance intervals and tasks required to keep these units operating safely.

td>td>td>td>

| Maintenance Task | Frequency | Purpose |

| Visual External Inspection | Identify corrosion, dents, or vandalism | |

| Internal Component Check | Ensure no gas leaks or regulator ice buildup | |

| Vent Stack Verification | Ensure unobstructed gas flow for safety relief | |

| Door Gasket and Lock Test | Maintain weather seal and security |

In summary, the Gas Pressure Regulating Box is a critical component in the safe delivery of energy. Whether deploying an outdoor gas pressure regulator enclosure for a residential subdivision, a weatherproof gas regulator housing for a commercial complex, or a heavy-duty industrial natural gas regulator cabinet for a manufacturing plant, the importance of quality cannot be overstated. These enclosures protect vital equipment, ensure public safety, and facilitate efficient energy distribution. By choosing a manufacturer that prioritizes durability, compliance, and design innovation, stakeholders can ensure that their gas infrastructure remains reliable for decades to come.

The primary function of a Gas Pressure Regulating Box is to house and protect gas pressure regulators and related meters from environmental hazards and physical tampering. By providing a secure, weatherproof environment, the box ensures that the sensitive internal equipment can reduce high-pressure gas to a safe, usable level without failing due to rust, ice, or impact damage.

An outdoor gas pressure regulator enclosure handles freezing temperatures through thermal insulation and sometimes active heating systems. The box is designed to retain the latent heat generated by the pressure regulation process or utilizes heat trace lines to prevent the regulator from freezing up. Additionally, the enclosure minimizes wind chill exposure, which is a common cause of equipment failure in open-pipe installations.

For a high pressure gas regulator box, heavy-gauge galvanized steel or stainless steel is recommended. These materials offer the structural strength required to withstand high-pressure forces and provide excellent resistance to corrosion. Stainless steel is particularly preferred in harsh environments or coastal areas where salt spray is a concern.

Yes, an industrial natural gas regulator cabinet must adhere to strict ventilation codes. These typically require that any relief vents be piped vertically to a safe elevation, often above the roofline, to prevent flammable gas from accumulating near the ground or near building intakes. The cabinet design must also facilitate cross-ventilation to prevent gas pockets from forming inside the unit.

A gas station pressure regulating cabinet should undergo a visual inspection at least monthly to check for damage or tampering. A comprehensive internal inspection and pressure test should be conducted annually or semi-annually by a certified technician to ensure that all regulators, valves, and safety devices are functioning correctly and that the enclosure's weather seals remain intact.

Contact Us